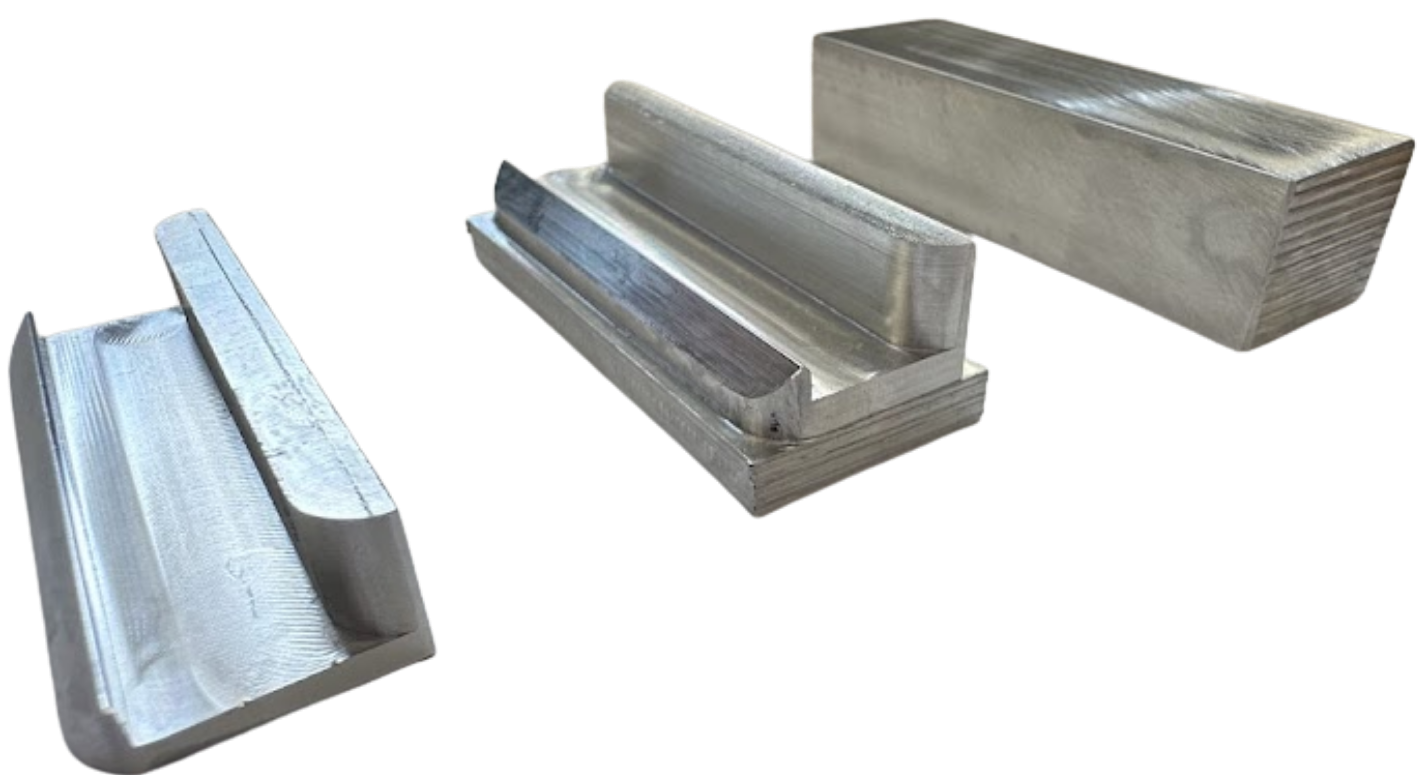

Custom Aluminium Components & Fasteners

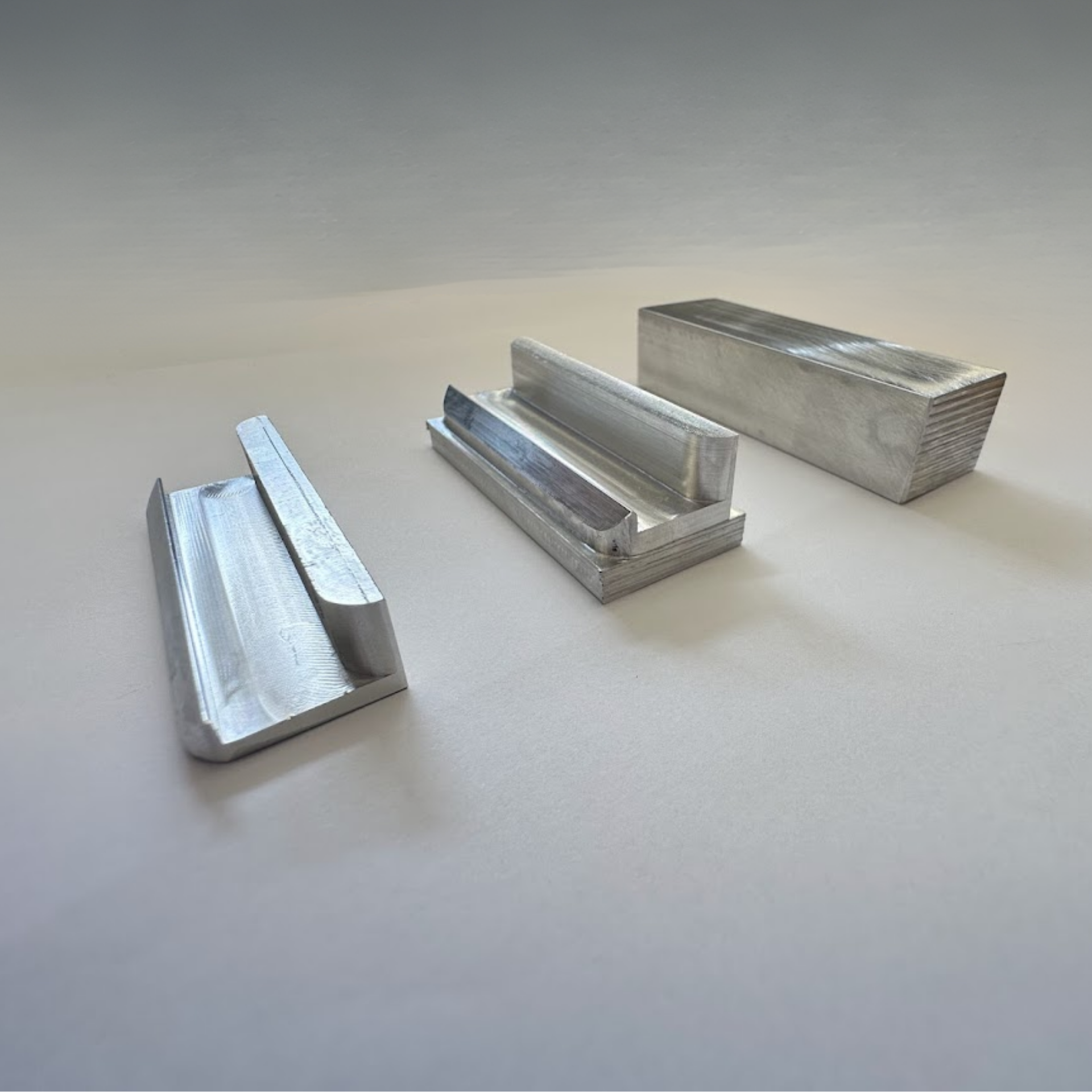

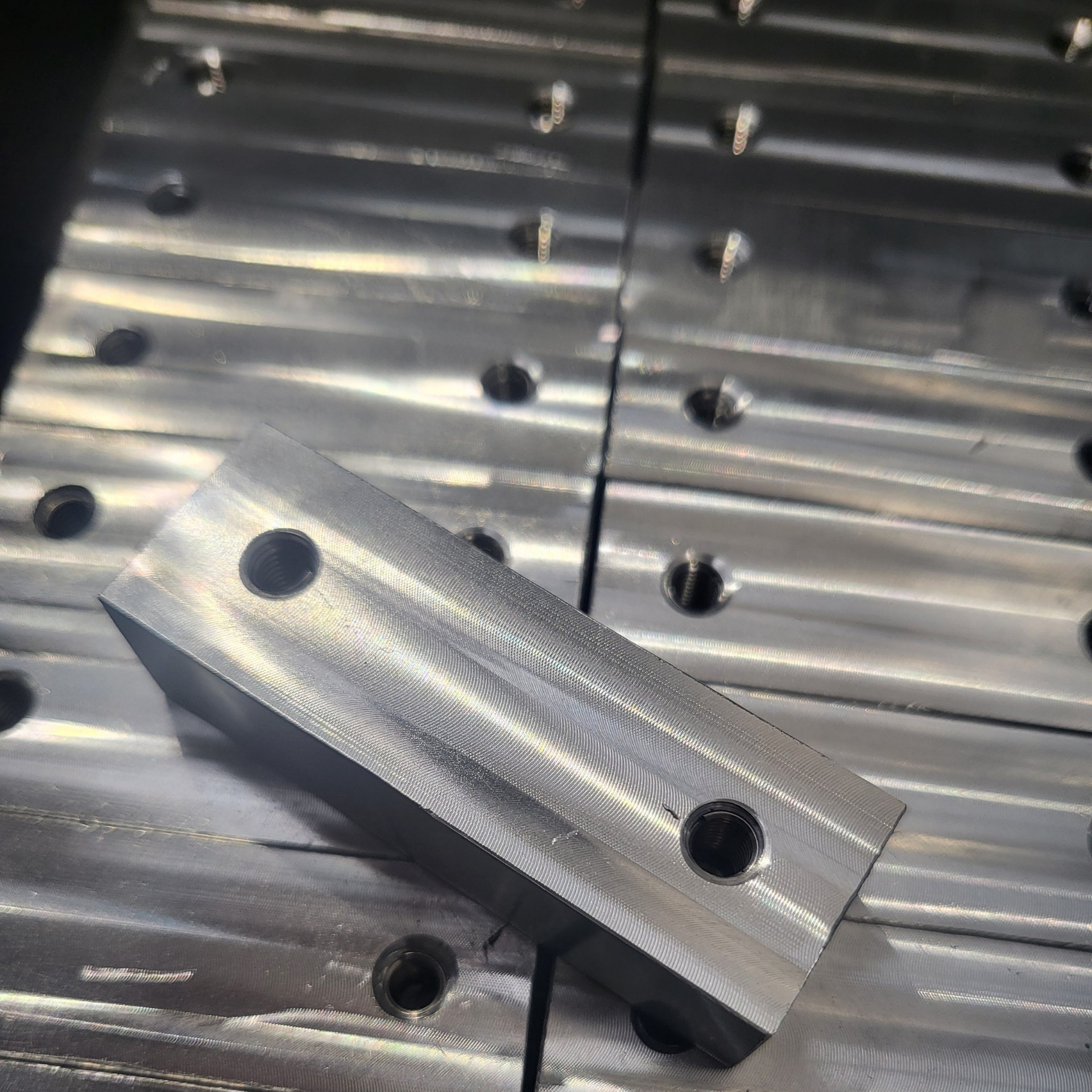

We specialise in the machining and turning of both basic and complex aluminium components, parts & fasteners.

We make quality aluminium parts & components to exacting designs

We manufacture precision aluminium parts such as fasteners, brackets, plates, housing, fittings, or structural elements via CNC milling and turning. Different aluminium grades or alloys are selected based on their machinability, strength, corrosion resistance, and anodising capability. We produce parts for a wide range of industries and applications from small batches to large quantities.

What type of aluminium do we typically work with?

Here's a selection of typical aluminium grades that we work with

- 6061 Aluminium

- Most widely used general-purpose alloy

- Good strength, excellent machinability

- Corrosion-resistant, weldable, and anodises well

- Common in: structural parts, brackets, frames, marine fittings, automotive and aerospace components

- 6082 Aluminium (primarily used in the UK & EU)

- Similar to 6061 but with slightly higher strength

- Excellent for structural and load-bearing applications

- Weldable and corrosion-resistant

- Common in: structural supports, transport components, architectural applications

- 7075 Aluminium

- High strength, comparable to some steels

- Less corrosion-resistant than 6061 but stronger

- Not ideal for welding

- Common in: aerospace parts, high-stress mechanical components, military hardware, performance motorsport parts

- 2024 Aluminium

- Very high strength-to-weight ratio

- Excellent fatigue resistance

- Poor corrosion resistance unless coated

- Common in: aerospace structures, aircraft fuselages, stressed components

- 5083 Aluminium

- Outstanding corrosion resistance, especially in marine environments

- Good weldability

- Moderate strength, not heat-treatable

- Common in: boat hulls, marine structures, tanks and offshore equipment

- 1050 / 1060 / 1100 Series (Pure Aluminium)

- High electrical and thermal conductivity

- Very soft, excellent formability

- Not suitable for structural parts

- Common in: electrical components, reflectors, HVAC parts, chemical tanks

All aluminium components are manufactured in the UK, here in the Midlands, and are subject to our ISO 9001:2015 quality system. From small batches to big orders, we provide competitive prices. Get in touch today or send us a drawing.

Why choose aluminium components?

Aluminium is one of the most versatile and widely used materials in modern manufacturing. Lightweight yet strong, corrosion-resistant and highly machinable, it offers an ideal balance of performance and economy. From structural frames to precision-machined fittings, aluminium components are trusted across aerospace, automotive, marine and industrial sectors.

Lightweight Strength

Aluminium delivers impressive strength relative to its weight. This makes it a natural choice where performance and load-bearing capacity must be achieved without adding unnecessary mass. In automotive and aerospace applications, aluminium components help reduce overall system weight, improving fuel efficiency and supporting more agile designs.

Excellent Machinability

Aluminium’s natural machinability makes it well-suited to high-precision manufacturing. Whether it’s CNC milling, turning or drilling, aluminium responds cleanly and consistently, allowing for tight tolerances and detailed finishes. This makes it ideal for complex geometries, repeatable part production and cost-effective turnaround times.

Corrosion Resistance

Naturally resistant to corrosion, aluminium performs well in a wide range of environments. When anodised or surface-treated, it becomes even more durable, making it suitable for outdoor use, marine settings and applications exposed to moisture or chemicals. This longevity reduces maintenance requirements and extends the life of the finished product.

Thermal and Electrical Conductivity

Aluminium components are often used where heat or electrical conductivity is important. In electronics and thermal systems, aluminium provides efficient heat dissipation and can be incorporated into housings, heat sinks or enclosures. It offers both structural support and functional performance in one material.

Flexible in Application

From simple brackets and plates to precision-engineered housings and fittings, aluminium can be shaped and finished to suit a wide variety of needs. It is available in numerous alloys, each tailored to deliver specific mechanical or thermal characteristics. Whether used for high-strength load-bearing parts or finely detailed assemblies, aluminium provides a highly adaptable solution.

Proven Performance Across Industries

In transportation, defence, electronics and manufacturing, aluminium components continue to prove their value. They offer a combination of performance, durability and efficiency that makes them a trusted choice for engineers and designers worldwide. When strength, accuracy and long-term reliability are required, aluminium delivers.