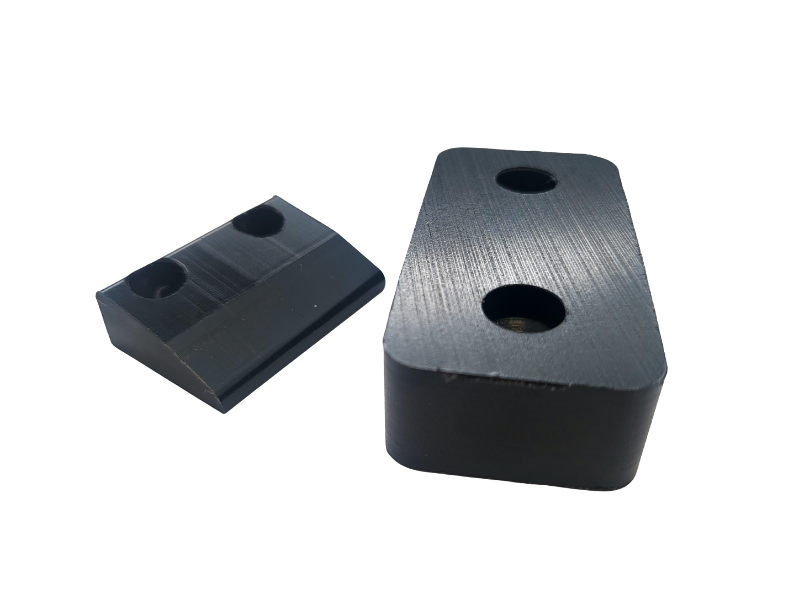

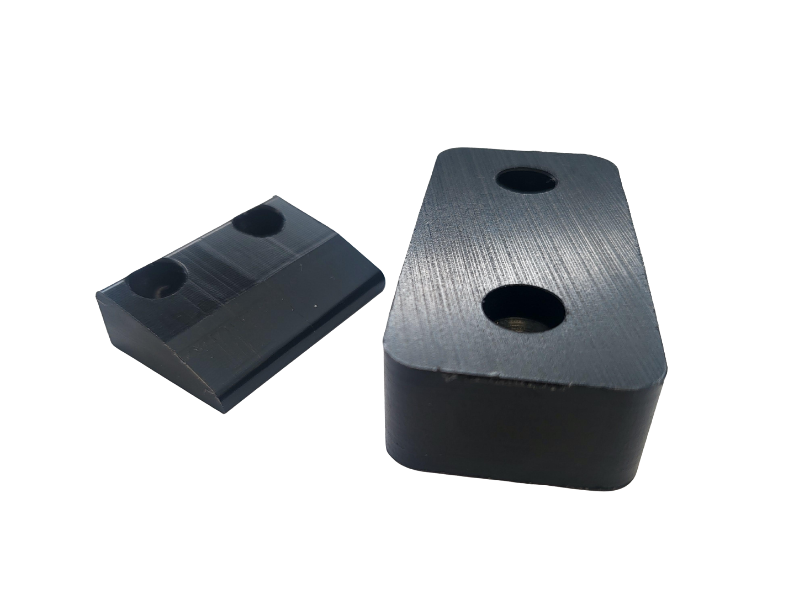

Plastic Components & Fasteners

We specialise in the machining and turning of both basic and complex plastic components, fasteners and parts.

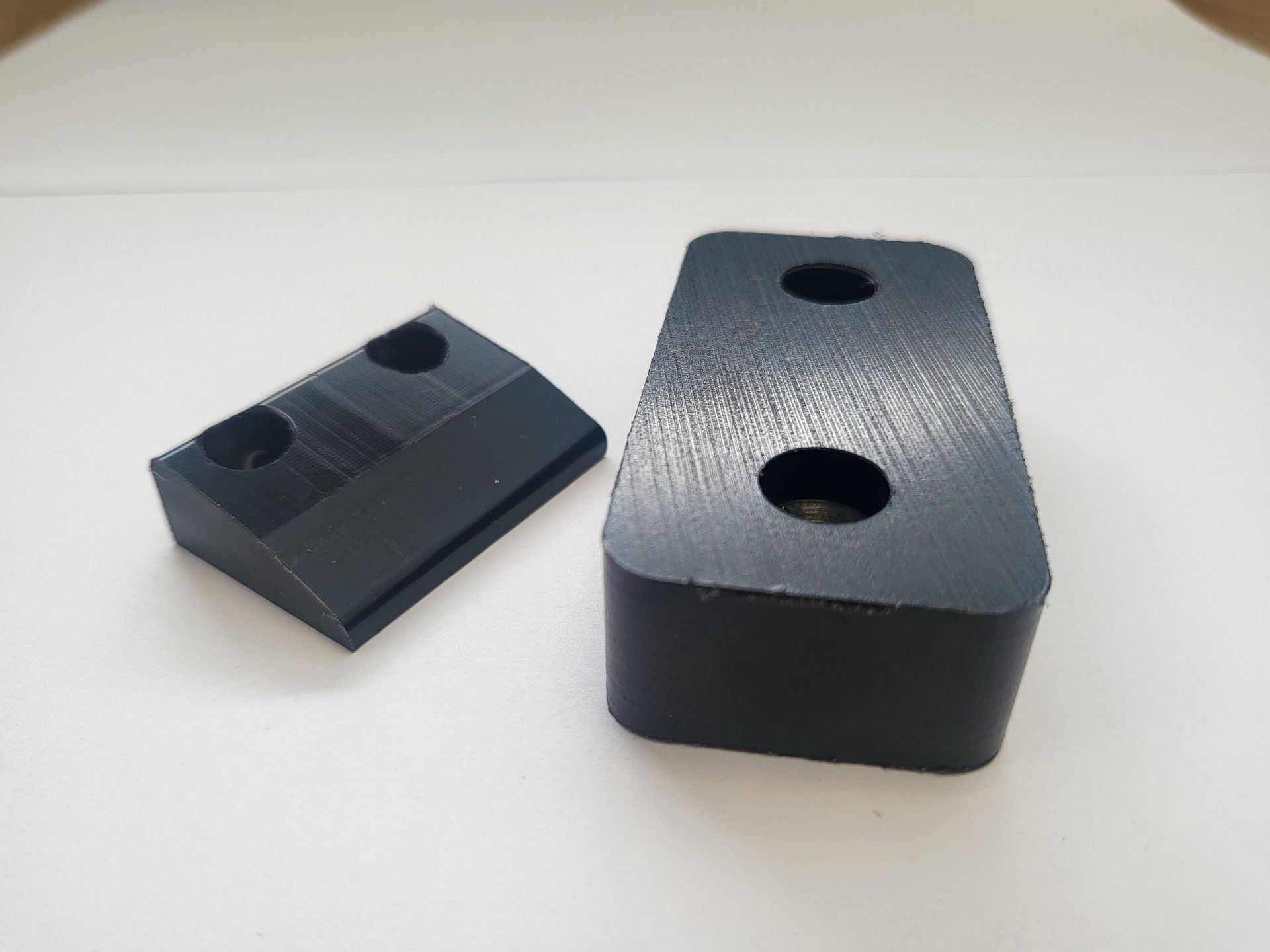

We make quality plastic components to exacting designs

Alongside metal components we make a wide range of turned and milled plastic components to order, catering for small batch, repeating orders or large batch orders.

Engineering plastics have a wide variety of industrial applications; they give unique physical, mechanical, and thermal properties, lending themselves to a wide range of sectors and specialist applications. We produce a wide range of plastics, including nylon. These hard-wearing components are especially effective in medical, lightweight, automotive, electronics, and much more.

What type of plastics do we typically work with?

When it comes to turning and milling plastic components, such as fasteners, bushings, or precision parts, certain plastics stand out due to their machinability, dimensional stability, strength, and thermal resistance.

High Performance

- POM (Polyoxymethylene) / Acetal / Delrin

- PTFE (Polytetrafluoroethylene)

- PEEK (Polyetheretherketone)

- PAI (Polyamide-imide) / Torlon

Engineering

- Nylon (PA6, PA66)

- UHMW-PE (Ultra High Molecular Weight Polyethylene)

- ABS (Acrylonitrile Butadiene Styrene)

- PVC (Polyvinyl Chloride)

- Polycarbonate (PC)

Speciality

- PEI (Ultem)

- PVDF (Polyvinylidene Fluoride)

All components are manufactured in the UK, here in the Midlands, and are subject to our ISO 9001:2015 quality system. From small batches to big orders, we provide competitive prices. Get in touch today.

Why choose plastic components?

When performance, reliability and resistance to environmental stress are critical, polymer fasteners present a smart alternative to metal. With excellent corrosion resistance, electrical insulation and weight-saving advantages, they are fast becoming the preferred choice across sectors including electronics, automotive, aerospace and industrial manufacturing.

Engineered for Demanding Environments

Unlike traditional metal fasteners, polymer alternatives do not rust, corrode or degrade in the presence of moisture, salt or aggressive chemicals. This makes them ideal for applications in marine engineering, chemical processing and outdoor infrastructure. In coastal environments, for example, polymer fixings offer long-term durability where metal components would require ongoing maintenance or early replacement.

Naturally Non-Conductive

In electrical and electronic systems, polymer fasteners provide crucial insulation. Materials such as nylon and PEEK are non-conductive, ensuring safe separation between components and helping to prevent short circuits or signal interference. They are widely used in circuit board assemblies, housings and control panels, offering reliability in sensitive environments.

Lighter by Design

Polymer fasteners are significantly lighter than their metal counterparts, making them a strong choice in weight-sensitive applications. In automotive interiors and aerospace systems, reduced weight contributes directly to improved efficiency and performance. Polymer clips, screws and fittings help manufacturers lower assembly weight without compromising on strength or stability.

Designed for Compatibility

Available in a wide range of metric and imperial sizes, including M3, M6 and 1/4-20, polymer fasteners are produced in multiple head styles such as hex, pan and flat, with drive types including Phillips, slotted and hex. This flexibility ensures compatibility with most tooling and assembly systems, while simplifying integration into new or existing designs.

High-Performance Materials

From general-purpose nylon to high-performance materials like PEEK, polymer fasteners are engineered to deliver reliable mechanical strength and stability. Many options maintain performance at elevated temperatures and in chemically aggressive environments, supporting consistent operation in both static and dynamic systems.

Proven Across Industries

Whether they are used to secure panels in a marine setting, insulate components in an electronic device or reduce weight in a structural assembly, polymer fasteners offer clear advantages. Built for challenging conditions and designed for long-term reliability, they are an intelligent solution where traditional metal fasteners may fall short.